Hammer Mill Screen Kuba Machine yokuSila

Iimpawu zeMveliso

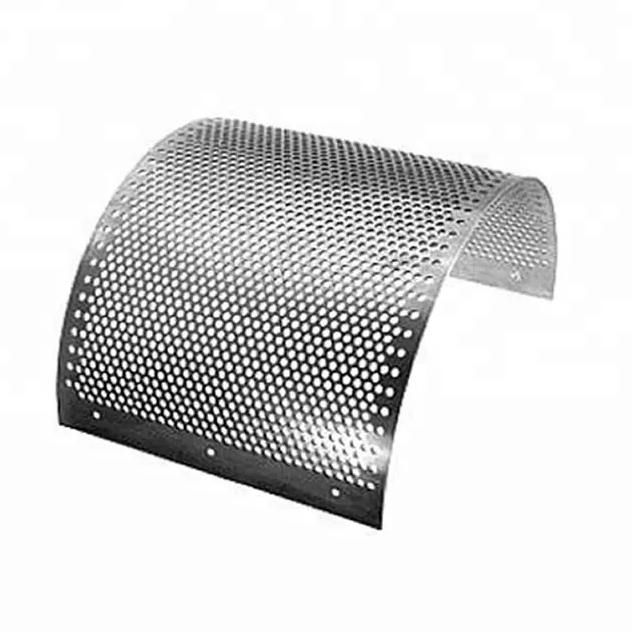

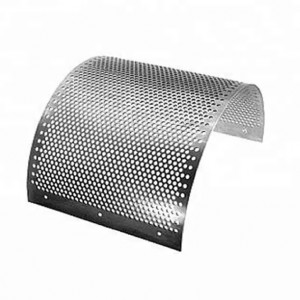

1. I-Hammer Screen yenye yezona ndawo zibalulekileyo ze-hammer mill, igcina i-hammer mill isebenza ngokufanelekileyo, kodwa ikwayinxalenye yokunxiba.

2. Iphepha lesikrini lisetyenziswe kwi-hammer mill kunye nesakhiwo esilula kunye nokuvelisa okulula, isikrini se-cylindrical sisetyenziswa kakhulu kwishishini.

3. Inempembelelo ebalulekileyo kwi-grinder. Ukuvula kunye nomgangatho wesikrini kunempembelelo ethe ngqo ekusebenzeni ngokufanelekileyo kunye nobomi bokusebenza kwesikrini.

4. Ubungakanani bomngxuma buhambelana nobukhulu bepellet. Inokucutshungulwa kwiintlobo ngeentlobo zemingxuma, njenge-0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm, kunye ne-4.0mm.

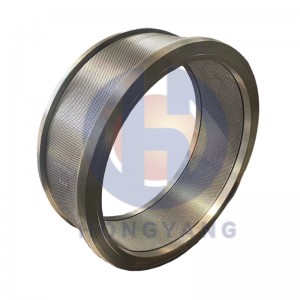

Uhlobo lwezikrini

Sinokubonelela ngezikrini ze-hammer mill zobukhulu obahlukeneyo. Ukuba nayiphi na kwezi zinto inomdla kuwe, nceda usazise. Siya kukuvuyela ukukunika ikowuti emva kokufumana iinkcukacha zakho ezicacileyo. Sineenjineli zethu zobuchwephesha be-R&D ukuhlangabezana nazo naziphi na iimfuno.

| Ukutyeba(mm) | Ububanzi bomngxuma(mm) | Umngxuma Area ratio | Unyamezelo lweDayimitha yomngxuma | Unyamezelo lweDayimitha yeZiko lomngxuma |

| 1.0 | 1.0 | 20% | ±0.05 | ±0.12 |

| 1.2 | 30% | ±0.05 | ±0.15 | |

| 1.2 | 1.2 | 30% | ±0.05 | ±0.15 |

| 1.5 | 33% | ±0.05 | ±0.15 | |

| 1.5 | 1.5 | 35% | ±0.06 | ±0.15 |

| 2.0 | 38% | ±0.06 | ±0.15 | |

| 1.8 | 1.8 | 40% | ±0.06 | ±0.15 |

| 2.5 | 48% | ±0.06 | ±0.15 | |

| 2.0 | 2.0 | 42% | ±0.06 | ±0.15 |

| 2.2 | 45% | ±0.07 | ±0.17 | |

| 2.5 | 48% | ±0.07 | ±0.17 | |

| 3.0 | 52% | ±0.07 | ±0.17 | |

| 3.2 | 55% | ±0.07 | ±0.17 | |

| 3.5 | 58% | ±0.07 | ±0.17 | |

| 4.0 | 60% | ±0.07 | ±0.17 |