Ukulungelelaniswa kwesithuba phakathi kwe-roller yoxinzelelo kunye ne-ring mold ye-granulator yinxalenye ebalulekileyo yokusebenza kwegranulator. Ukuba ukulungiswa kwe-gap kunengqiqo, i-granulator iya kuba nemveliso ephezulu, ukusetyenziswa kwamandla aphantsi, umgangatho omhle we-particle, ukugqoka okuphantsi kwe-roller yoxinzelelo kunye ne-ring mold, kunye nobomi obude benkonzo.

I-granulator ayikwazi ukusebenza ngokufanelekileyo, umgangatho we-particle awuqinisekiswanga, kwaye ukuba i-gap phakathi kwe-roller yoxinzelelo kunye ne-ring mold incinci kakhulu, iya kunxiba kakhulu, kwaye ibangele ukuba i-mold ring iqhume. Oku kubeka phambili iimfuno eziphezulu kubaqhubi begranulator, abafuna ukuba nolwazi olutyebileyo lohlengahlengiso lwe-roller yoxinzelelo. Ukuze kuncitshiswe impembelelo yezinto ezingazinzanga ezibangelwa yimisebenzi yabantu, kunye nokunciphisa umsebenzi womntu kunye nokuphucula ukusebenza kakuhle kwemveliso.

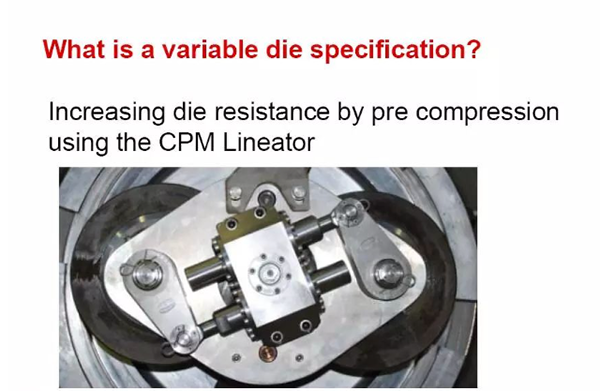

Itekhnoloji yohlengahlengiso oluzenzekelayo kwisithuba phakathi kwe-roller yoxinzelelo kunye ne-ring mold ivele.

Imigaqo yobugcisa:

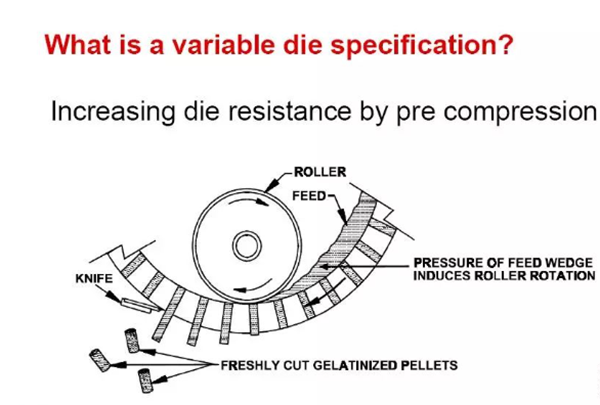

Inkqubo iqulunqwe kakhulu yinkqubo yokubulawa kwe-oil cylinder, i-angle sensor, kunye nenkqubo yokulawula i-PLC. Umsebenzi we-oil cylinder execution system kukutyhala i-roller yoxinzelelo ukuba ijikeleze i-clockwise okanye i-counterclockwise, nokuba i-gap phakathi kwe-roller yoxinzelelo kunye ne-ring mold iyanda okanye iyancipha;

Umsebenzi we-angle sensor kukuva utshintsho kwi-angle ye-roller yoxinzelelo kunye nokuhambisa umqondiso wokutshintsha kwinkqubo yokulawula ye-PLC; Inkqubo yokulawula i-PLC inoxanduva lokuguqula utshintsho kwi-angle ye-roller yoxinzelelo kwinguqu kwisayizi ye-gap phakathi kwe-roller yoxinzelelo kunye ne-ring mold, kunye nokuthelekisa kunye nexabiso elibekiweyo le-gap ukumisela ulwalathiso kunye nobukhulu benkqubo yokubulawa kwe-oil cylinder de kube i-gap yangempela kunye ne-gap iseti iyahambelana phakathi koluhlu oluvumelekileyo lwephutha.

Iinzuzo zobugcisa:

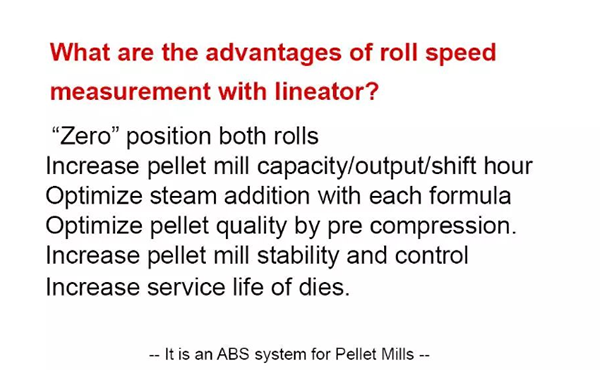

Isikrini se-touch screen sisebenza njengojongano olusebenzayo, okwenza kube lula ukusebenza;

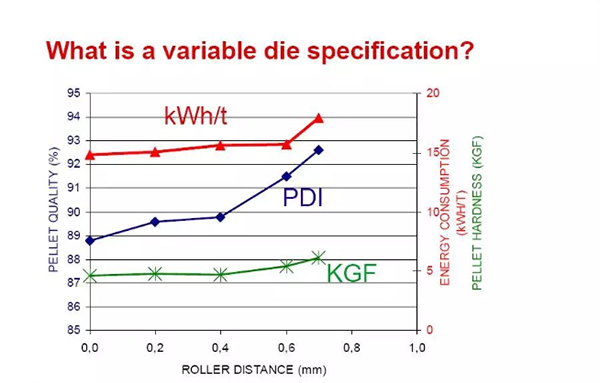

Ukunciphisa isinyithi kwintsimbi, ukunciphisa ukunxiba kwi-roller yoxinzelelo kunye ne-ring mold, ukwandisa kakhulu ubomi benkonzo;

Ukunciphisa imfuno yombane, ukunciphisa ixesha lokuphumla, kunye nokugcina ixesha kunye neendleko;

Ukuchaneka kokulungelelaniswa okuphezulu, impazamo ye-gap phakathi kwe-roller yoxinzelelo kunye ne-ring mold inokulawulwa ngaphakathi kwe-± 0.1mm;

Inokulungiswa nangaliphi na ixesha ngexesha lokusebenza kwegranulator, iphucula kakhulu ukuthembeka komsebenzi kunye nokusebenza kakuhle, kunye nokunciphisa amandla omsebenzi;

Akukho ioli yokuthambisa, ukwandisa ukhuseleko lokutya.

Ixesha lokuposa: Jul-12-2023