Ngethuba lenkqubo ye-granulation yomatshini we-pellet yokutya, kukho iipelisi zokutya zomntu ngamnye okanye iipellets zokutya ezinemibala eyahlukeneyo, eyaziwa ngokuba yi "flower feed". Le meko ixhaphakile ekuvelisweni kokutya kwasemanzini, ikakhulu kubonakaliswe njengombala wamasuntswana ngamnye akhutshwe kwi-ring ring ibe mnyama okanye ibe khaphukhaphu kunamanye amasuntswana aqhelekileyo, okanye umbala womphezulu wamasuntswana ngamnye ungahambelani, ngaloo ndlela uchaphazela imbonakalo yomgangatho webhetshi yonke yokutya.

Ezona zizathu ziphambili zale meko zezi zilandelayo:

a)Ukubunjwa kwemathiriyeli yesondlo ekrwada kuntsonkothile kakhulu, kukho iintlobo ezininzi zemathiriyeli ekrwada, ukuxubana okungalinganiyo, kunye nomxholo wokufuma ongahambelaniyo womgubo phambi kokulungiswa kwamasuntswana okutya.

b)Isiqulatho sokufuma semathiriyeli ekrwada esetyenziselwa igranulation ayihambelani. Kwinkqubo yokuvelisa ukutya kwamanzi, kudla ngokuyimfuneko ukongeza inani elincinci lamanzi kumxube ukuze uhlawule ukulahlekelwa kwamanzi kwizinto eziluhlaza emva kokutyunyuzwa kwe-ultrafine. Emva kokuxuba, emva koko ithunyelwa kwi-conditioner yokufudumala. Abanye abavelisi bezondla basebenzisa inkqubo elula kakhulu yokwenza isondlo - beka izinto ezifunekayo kwifomula ngqo kumxube kwaye bongeze amanzi aneleyo, endaweni yokuqhubela phambili inkqubo yokongeza eneenkcukacha kunye necothayo ngokweemfuno zobungcali. Ngoko ke, bakufumanisa kunzima ukuqinisekisa ulwabiwo olulungeleleneyo lwezithako zokutya ngokwemiqathango yokunyibilika kwamanzi. Xa sisebenzisa ezi zithako ezixubeneyo zonyango lwe-conditioning, siya kufumanisa ukuba ngenxa yokusebenza kakuhle kwe-conditioner, umxholo womswakama awukwazi ukusasazwa ngokukhawuleza. Ke ngoko, ukuvuthwa kweemveliso ezicutshungulwayo zesondlo phantsi kwesenzo somphunga kuyahluka kakhulu phakathi kwamacandelo ahlukeneyo, kwaye i-hierarchy yombala emva kwegranulation ayicaci ngokwaneleyo.

c)Kukho izinto ezihlaziyiweyo ezinegranulation ephindaphindiweyo kumgqomo wegranulation. Izinto zegranular emva kwegranulation zingatshintshwa kuphela kwimveliso egqityiweyo emva kokuba ipholile kwaye ihlolwe. I-powder ecocekileyo efihliweyo okanye i-particle encinci ingena rhoqo kwinkqubo yokuvelisa i-re granulation, ngokuqhelekileyo kwi-mixer okanye ilinde i-granulation silo. Ngenxa yokuba olu hlobo lwezinto ezibuyiswayo zilungiswa ngokutsha kwaye zihlanjululwe, ukuba zixutywe ngokungafaniyo nezinye izinto ezincedisayo okanye zixutywe nomatshini wokubuyisela izinto ezincinci emva kokulungiswa, ngamanye amaxesha kunokuvelisa "izinto zeentyatyambo" kwiifomyula ezithile zokutya.

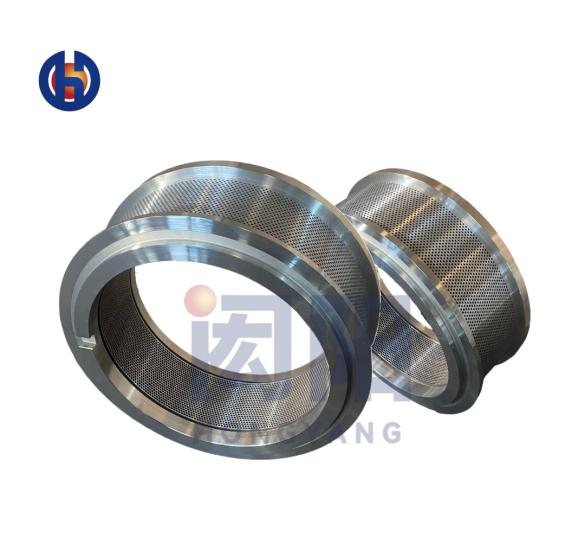

d)Ukuguda kodonga lwangaphakathi lwendandatho yokufa ayihambelani. Ngenxa yokungahambelani kokugqiba komphezulu womngxunya wokufa, ukuxhathisa kunye noxinzelelo lwe-extrusion ukuba into eyenzeka ngayo ngexesha le-extrusion iyahluka, okukhokelela ekutshintsheni kombala okungahambelaniyo. Ukongeza, enye i-ring dies ine-burrs kwiindonga zomngxuma omncinci, ezinokukrwela umphezulu wamasuntswana ngexesha lokukhupha, okukhokelela kwimibala eyahlukileyo yendawo yamasuntswana ngamanye.

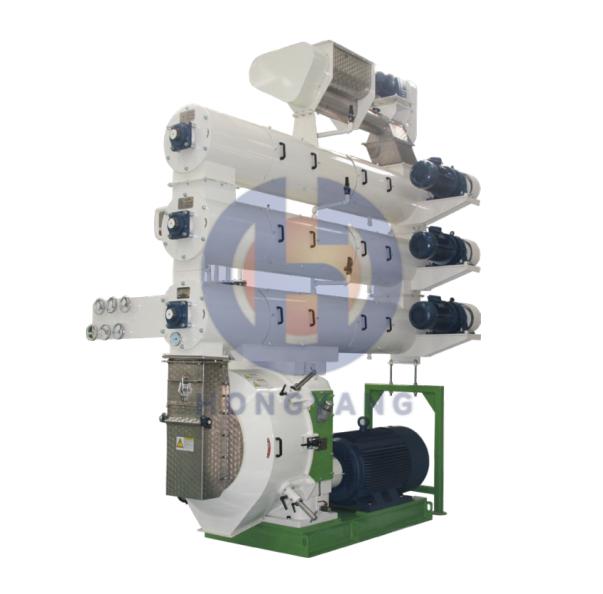

Iindlela zokuphucula ngenxa yezizathu ezine zokuvelisa "izinto zeentyatyambo" ezidweliswe ngasentla sele zicacile, ngokukodwa zilawula ukuxubana kokuxubana kwecandelo ngalinye kwifomula kunye nokudibanisa ukudibanisa kwamanzi adityanisiweyo; Ukuphucula ukusebenza kokucima kunye nokufudumala kunokunciphisa utshintsho lombala; Lawula umatshini wokubuyisela izinto. Kwiifomula ezithambekele ekuveliseni "izinto zeentyatyambo", zama ukuba ungafaki ngokuthe ngqo umatshini wokubuyisela. Izinto zokubuyisela umatshini kufuneka zixutywe kunye nezinto eziluhlaza kwaye zityunyuzwe kwakhona; Sebenzisa ezikumgangatho ophezulu ring dies ukulawula ukugudiseka imingxuma die, kwaye ukuba kuyimfuneko, sila umngxunya die umsesane phambi kokusetyenziswa.

Kuyacetyiswa ukuba uqwalasele i-conditioner yokwahlukana kwe-axis ephindwe kabini kunye ne-two-layer eyandisiweyo yejacket conditioner, kunye nexesha lokucima ukuya kwi-60-120 imizuzwana kunye nobushushu bokucima obungaphezulu kwe-100 ℃. Ukucima kufana kwaye ukusebenza kuhle kakhulu. Ukusetyenziswa kweendlela ezininzi zokungenisa umoya kwandisa kakhulu indawo enqamlezileyo yezinto eziphathekayo kunye ne-steam, ngaloo ndlela kuphuculwe ukuvuthwa kwezinto kunye nokuphucula umphumo wokucima kunye nokufudumala; Iphaneli yesixhobo sedijithali kunye nenzwa yeqondo lokushisa ingabonisa ubushushu bemeko, okwenza kube lula kubasebenzisi ukulawula nangaliphi na ixesha.

Ulwazi loQhagamshelwano lweNkxaso yobuGcisa:

Whatsapp : +8618912316448

I-imeyile:hongyangringdie@outlook.com

Ixesha lokuposa: Jul-26-2023