Kwi-pellet feed processing, izinga eliphezulu lokucolwa alichaphazeli nje kuphela umgangatho wokutya, kodwa likwanyusa iindleko zokusetyenzwa. Ngokuhlolwa kwesampulu, izinga le-pulverization yesondlo sinokubonwa ngokubonakalayo, kodwa akunakwenzeka ukuqonda izizathu zokuxutywa kwenkqubo nganye. Ngoko ke, kucetyiswa ukuba abavelisi bezondlo bomeleze ukubeka iliso okusebenzayo kwicandelo ngalinye kwaye baphumeze amanyathelo okuthintela nokulawula ngaxeshanye.

1, Yondla ifomula

Ngenxa yomahluko kwimixube yesondlo, ubunzima bokucubungula bunokwahluka. Ngokomzekelo, ukutya okuneprotheyini ekrwada ephantsi kunye nomxholo we-fat kulula ukugranulate kunye nokucutshungulwa, ngelixa ukondla okunomxholo ophezulu kungenakwenzeka ukuba kwenzeke, okubangelwa amaqhekeza akhululekile kunye nezinga eliphezulu le-pulverization. Ngoko ke xa kuqwalaselwa feed granulation ngokubanzi, ifomula yeyona nto ifunekayo, kunye nobunzima processing kufuneka kuqwalaselwe kangangoko ukuqinisekisa quality.Njengoko umthengi Hongyang Feed Machinery, sinokukunika iifomyula feed yobungcali ukwandisa umthamo wakho imveliso kunye nokuphucula umgangatho feed.

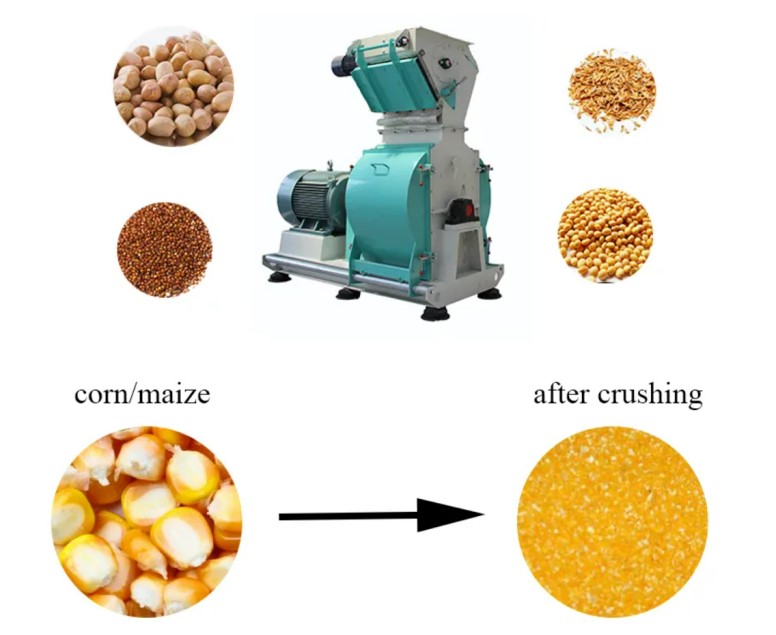

2, Icandelo lokutyumza

Incinci isayizi ye-particle ye-raw material crushing, inkulu indawo engaphezulu kwezinto, i-adhesion engcono ngexesha le-granulation, kwaye iphezulu umgangatho we-granulation. Kodwa ukuba incinci kakhulu, iya kutshabalalisa ngokuthe ngqo izondlo. Ukukhetha ubungakanani bezinto ezahlukeneyo ezityumzayo ezisekelwe kwiimfuno ezibanzi zomgangatho kunye nolawulo lweendleko kubalulekile. Ingcebiso: Ngaphambi kokutyalwa kwemfuyo kunye nokutya kweenkukhu, ubukhulu beqhekeza lomgubo kufuneka bube ubuncinane be-16 mesh, kwaye ngaphambi kokuba i-pelletizing feed yasemanzini, i-particle size ye powder kufuneka ibe yi-40 mesh ubuncinane.

3, icandelo leGranulation

Umxholo wamanzi aphantsi okanye aphezulu, ubushushu obuphantsi okanye obuphezulu bobushushu bonke banempembelelo enkulu kumgangatho we-granulation, ngakumbi ukuba baphantsi kakhulu, baya kwenza ukuba i-granulation ye-fid particles ingaqini, kwaye izinga lomonakalo we-particle kunye ne-pulverization rate iya kwanda. Iingcebiso: Lawula isiqulatho samanzi ngexesha lokufudumeza phakathi kwe-15-17%. Ubushushu: 70-90 ℃ (i-inlet umphunga kufuneka ucinezeleke ukuya kuma-220-500kpa, kwaye ubushushu bomphunga wokungena kufuneka ulawulwe malunga ne-115-125 ℃).

4. Icandelo lokupholisa

Ukupholisa okungalinganiyo kwemathiriyeli okanye ixesha lokupholisa ngokugqithisileyo kunokubangela ukugqabhuka kwamasuntswana, okukhokelela kummandla wesondlo ongaqhelekanga kunye nokwaphuka lula, ngoko konyusa izinga lokucolwa. Ngoko kuyimfuneko ukukhetha izixhobo ezithembekileyo zokupholisa kunye nokupholisa ngokulinganayo amaqhekeza.

5. Icandelo lokuhlola

Ubukhulu obugqithisileyo okanye ukusabalalisa okungafaniyo komgangatho wezinto eziphathekayo zesikrini kunokukhokelela ekuhlolweni okungaphelelanga, okukhokelela ekunyuseni komxholo we powder kwimveliso egqityiweyo. Ukukhutshwa ngokukhawuleza kwepholileyo kunokubangela ngokulula ukutyeba okugqithisileyo komgangatho we-sieve umaleko, kwaye ingqwalasela kufuneka ihlawulwe ekuthinteleni.

6, Icandelo lokuPakisha

Inkqubo yokupakisha imveliso egqityiweyo kufuneka iqhutywe kwinkqubo yokuvelisa eqhubekayo, kunye ne-warehouse yemveliso egqityiweyo igcina ubuncinane i-1/3 yemveliso egqityiweyo ngaphambi kokuqala ukupakisha, ukwenzela ukuba ugweme ukwanda kwepowder kwimveliso egqityiweyo ebangelwa yi-feed ewela kwindawo ephezulu.

Ixesha lokuposa: Oct-24-2023