Kwimveliso yangempela yokutya, ngenxa yezizathu ezahlukahlukeneyo, "imbiza yezinto eziphathekayo" inokwakheka phakathi kweringi kunye ne-roller yoxinzelelo, ekhokelela kwiingxaki ezifana ne-jamming, ukuvaleka, kunye nokutyibilika kwegranulator.

Sifumene ezi zigqibo zilandelayo ngohlalutyo olusebenzayo kunye namava kwindawo yetyala:

Sifumene ezi zigqibo zilandelayo ngohlalutyo olusebenzayo kunye namava kwindawo yetyala:

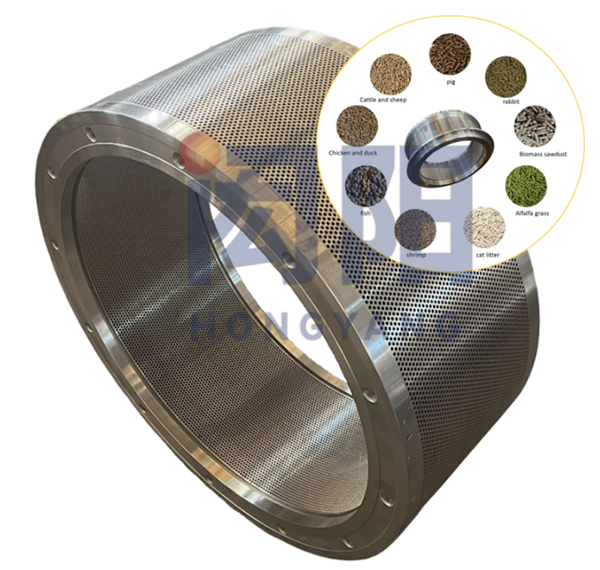

1, Imiba yemathiriyeli ekrwada

Izinto ezinomxholo ophezulu wesitashi zixhomekeke kwi-gelatinization ye-steam kwaye zine-viscosity ethile, ehambelana nokubumba; Kwizixhobo ezinemicu ephezulu erhabaxa, ubungakanani begrisi kufuneka bongezwe ukuze kuncitshiswe ukungquzulana ngexesha lenkqubo yegranulation, nto leyo enenzuzo yokuba izinto zidlule kwisikhunta sendandatho kunye nesiphumo segranular sibonakala sigudile.

2, Ukukhutshwa okungafanelekanga komqulu wokufa

Umsantsa phakathi kwe-mold rollers inkulu kakhulu, ibangela ukuba umaleko wezinto eziphathekayo phakathi kwe-mold rollers ibe nzima kakhulu kwaye isasazwe ngokungalingani. I-roller yoxinzelelo ilungele ukutyibilika ngenxa yamandla angalinganiyo, kwaye izinto eziphathekayo azikwazi ukunyanzeliswa ngaphandle, okubangelwa ukuvala umatshini. Ukunciphisa ukuvinjelwa komatshini, ingqalelo kufuneka ihlawulwe ekulungiseni i-gap phakathi kwe-mold rollers ngexesha lokuvelisa, ngokuqhelekileyo i-3-5mm ikhethwa.

3, Impembelelo yomgangatho womphunga

3, Impembelelo yomgangatho womphunga

Iimeko ezifanelekileyo zenkqubo yegranulation zezi: isiqulatho sokufuma esifanelekileyo semathiriyeli ekrwada, umgangatho obalaseleyo womphunga, kunye nexesha elaneleyo lokufudumeza. Ukuqinisekisa umgangatho omhle wamasuntswana kunye nemveliso ephezulu, ngaphezu kokusebenza okuqhelekileyo kweendawo ezahlukeneyo zokuhanjiswa kwegranulator, umgangatho we-steam eyomileyo eyomileyo engena kwi-conditioner ye-granulator nayo kufuneka iqinisekiswe.

Umgangatho ophantsi we-steam ubangela ukufuma okuphezulu kwezinto eziphathekayo xa uphuma kwi-conditioner, enokubangela ukuba kube lula ukuvala umgodi wokubumba kunye nokutyibilika kwe-roller yoxinzelelo ngexesha lenkqubo ye-granulation, okubangelwa ukuvala umatshini. Ibonakaliswe ngokuthe ngqo kwi:

① Uxinzelelo olungonelanga lomphunga kunye nesiqulatho sokufuma okuphezulu kunokubangela lula ukuba imathiriyeli ifunxe amanzi amaninzi. Ngexesha elifanayo, xa uxinzelelo luphantsi, ubushushu xa izinto zifudumala nazo ziphantsi, kwaye isitashi asikwazi ukwenza i-gelatin kakuhle, okubangelwa yimpembelelo embi ye-granulation;

② Uxinzelelo lomphunga aluzinzanga, luguquguquka ukusuka phezulu ukuya ezantsi, kwaye umgangatho wezinto eziphathekayo awuzinzanga, okukhokelela ekuguquguqukeni okukhulu kwigranulator yangoku, ukunxanwa kwezinto ezingalinganiyo, kunye nokuvala lula ngexesha leenkqubo eziqhelekileyo zokuvelisa.

Ukunciphisa inani lokumisa umatshini okubangelwa umgangatho womphunga, abaqhubi befektri yokutya kufuneka bahlawule ingqalelo kumxholo womswakama wezinto emva kokutshisa nangaliphi na ixesha. Indlela elula yokumisela kukubamba izinto eziphathekayo kwi-conditioner kwaye uyibambe kwibhola, kwaye uyeke ukuba uyisasaze nje.

4, Ukusetyenziswa kweringi entsha kuyafa

4, Ukusetyenziswa kweringi entsha kuyafa

Ngokuqhelekileyo, xa i-ring entsha iqala ukusetyenziswa, kufuneka icolwe ngezinto ezinamafutha, ngokunyuka okufanelekileyo malunga ne-30% yesanti ye-emery, kunye nomhlaba malunga nemizuzu engama-20; Ukuba kukho izinto ezininzi kwigumbi le-granulation, kwaye i-current iyancipha xa ithelekiswa nokugaya, iyazinza, kwaye ukuguquguquka kuncinci. Ngeli xesha, umatshini unokumiswa kwaye imeko ye-granulation inokujongwa. Igranulation ifana kwaye ifikelela ngaphezu kwe-90%. Ngeli xesha, sebenzisa izinto ezinamafutha ukucinezela kwaye ubuyisele imathiriyeli yesanti ukuthintela ukuvaleka okulandelayo.

Ukuba i-ring ring ivaliwe ngexesha lenkqubo yokuvelisa, iifektri ezininzi zokutya zisebenzisa i-drills zombane ukuze zikhuphe izinto, eziza konakalisa ukugudiswa komngxuma wokubumba kwaye zibe yingozi kwi-aesthetics yamasuntswana.

Eyona ndlela ibhetele enconyelwayo kukubilisa ukungunda kweringi ngeoyile, okukukusebenzisa ipani yeoli yentsimbi, ugalele i-oyile ye-injini eyinkunkuma kuyo, untywilisele ukungunda okuvaliweyo kuyo, uze ufudumeze uze uyitshise emazantsi de kubekho isandi sokuqhekeka, uze uyikhuphe. Emva kokupholisa, ukufakela kugqityiwe, kwaye i-granulator iphinda iqaliswe ngokwemigaqo yokusebenza. Izinto ezithintela ukubunjwa kwendandatho zinokucocwa ngokukhawuleza ngaphandle kokonakalisa i-particle finish.

Ixesha lokuposa: Jul-19-2023