1.Ifomula yesondlo

I-Feed Raw Materials eqhelekileyo ngumbona, iSidlo seembotyi zesoya, ingqolowa, irhasi, izongezo njalo njalo. Esona sondlo siphezulu sinokwenziwa ngomlinganiselo ofanelekileyo wemathiriyeli. Njengabathengi beHongyang,siza kukubonelela ngeIfomula yokutyakwireferensi.

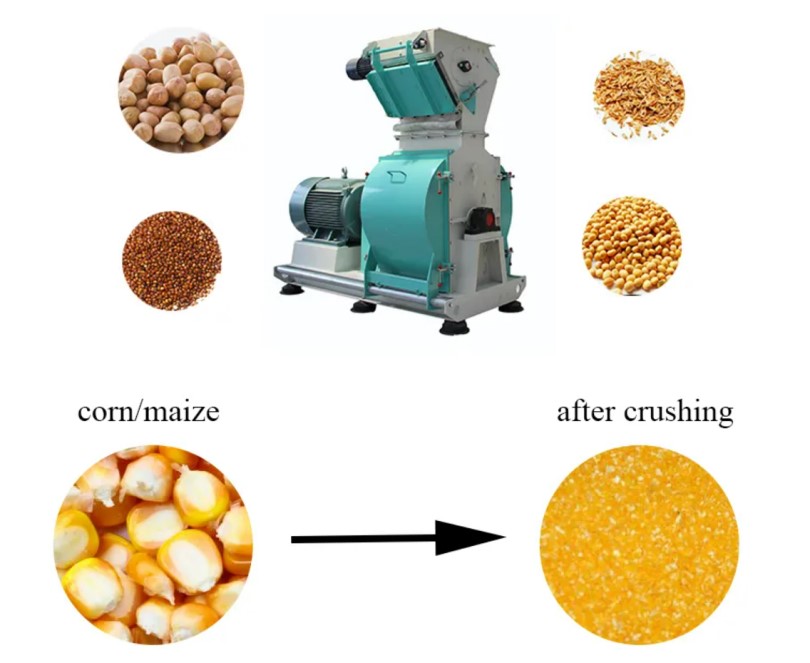

2. Ubungakanani beNcam ekrwada

Ngokuqhelekileyo kukholelwa ukuba Ukunciphisa Ubungakanani beNgxelo yempahla ekrwada kunenzuzo kumgangatho wamasuntswana. Nangona kunjalo, ukuze ugweme inkunkuma yombane kunye nokwehla kwemveliso, ukuCrushing ngokugqithiseleyo akukhuthazwa. Endaweni yoko, ubungakanani besuntswana elincinci liyacetyiswa.Hongyang SFSPuthothoIHammer Millayinakuqaphela kuphela iindidi ezintathu zokutyumza i-granularity, kodwa iphinde igcine ukusetyenziswa kwamandla.

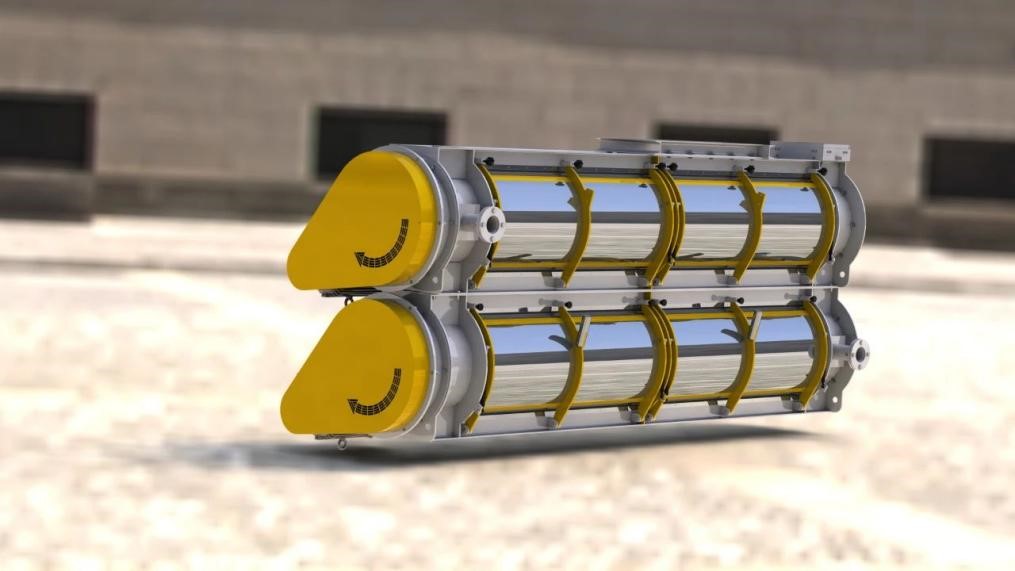

3. Iimeko zomphunga

Xa i-powder feed ingena kwi-Conditioner, iya kufumana unyango oluphezulu lwe-steam. Umphunga unika ubushushu kunye namanzi kwi-starch gelatinization, i-particle adhesion, i-predigestion, kunye nokutshatyalaliswa kwe-pathogen. Iqondo lokushisa kunye nexesha lokucubungula umphunga kwi-tuner zizinto eziphambili ezichaphazela ukuqina kwe-particle. Xa izinga lokushisa lidlula i-80 ° C, umgangatho ophezulu we-granular ungaveliswa, kwaye ixesha elifutshane lokucubungula yimizuzwana engama-30. Ubuninzi be-particle bunganyuswa ngokwandisa ixesha lokucima kunye nokufudumala ukuya kwi-3-4 imizuzu.Hongyangisilungisiigcwele i-thermal insulation rock wool, enokusebenza okungcono kokugquma kwe-thermal, ukonga amandla ngakumbi kunye nomgangatho ongcono.

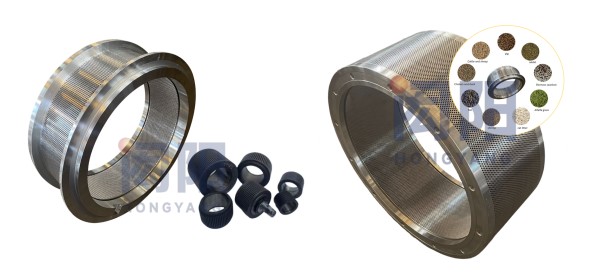

4. Ukucaciswa kweRingi Die/Pellet Press Die

Ukufa okutyebileyo ukuphucula umgangatho weepellets, ngenxa yokunyuka kweepellets zesondlo kunye nokukhuhlana phakathi kodonga lokufa, kunyuse izinga le-starch gelatinization. Nangona kunjalo, ukusebenzisa i-aperture engqingqwa okanye indawo encinci kunokunciphisa imveliso. Ukongezelela, umgama phakathi kwee-roller kunye nokufa kwanda ukusuka kwi-0.1 mm ukuya kwi-2 mm, kunokuphucula ukuqina kweepellets.

Iringi yokufa/ipellet yokucofa umgangatho wokufaHongyangUmatshini wokutyisa ungcono, uhlala ixesha elide, kwaye unomthamo ophezulu wemveliso. Sincoma kwaye wenze ngokwezifiso umlinganiselo ofanelekileyo woxinzelelo kunye nokuvula kubathengi.

5. Ukupholisa

Xa ushiya i-conditioner, ukushisa kwe-pellet feed yi-70-90 ° C kunye nomswakama we-15-17%. Ngexesha lokupholisa, iqondo lokushisa kufuneka lincitshiswe libe yi-5 ° C ngaphezu kweqondo lokushisa, kwaye umswakama kufuneka uncitshiswe kwi-12%. Ukupholisa okukhawulezayo kubangela ukuba umswakama kunye nobushushu phezu kobuso bamaqhekeza bube buphantsi kunokuba bungaphakathi kwiincinci, ezibangela iincinci ezinqabileyo. Nangona kunjalo, ixesha lokupholisa ixesha elide liya kukhokelela ekomisweni kakhulu kwamasuntswana, ukonyuka komyinge wokunxitywa kunye nokuncipha kwencasa.Hongyangngokuchaseneyoepholileyoisebenzisa umgaqo wokupholisa we-countercurrent ukupholisa amaqhekeza kunye nokushisa okuphezulu kunye nomswakama ophezulu, ukuphepha ukupholisa ngokukhawuleza okubangelwa ukudibanisa ngokuthe ngqo phakathi komoya obandayo kunye nezinto ezishushu, ngoko kunokuthintela ngokufanelekileyo amaqhekeza ekuqhekekeni komhlaba.

Ulwazi oluthe kratya malunga noShishino lokuTyelwa kunye nezichumisi ze-Organic, pls khangela apha ngezantsi:

umthombo: www.ringdies.com

Okanye uqhagamshelane nathi ngokuthe ngqo:

Ifowuni: +86 18912316448

E-mail: hongyangringdie@outlook.com

Ixesha lokuposa: Aug-31-2023