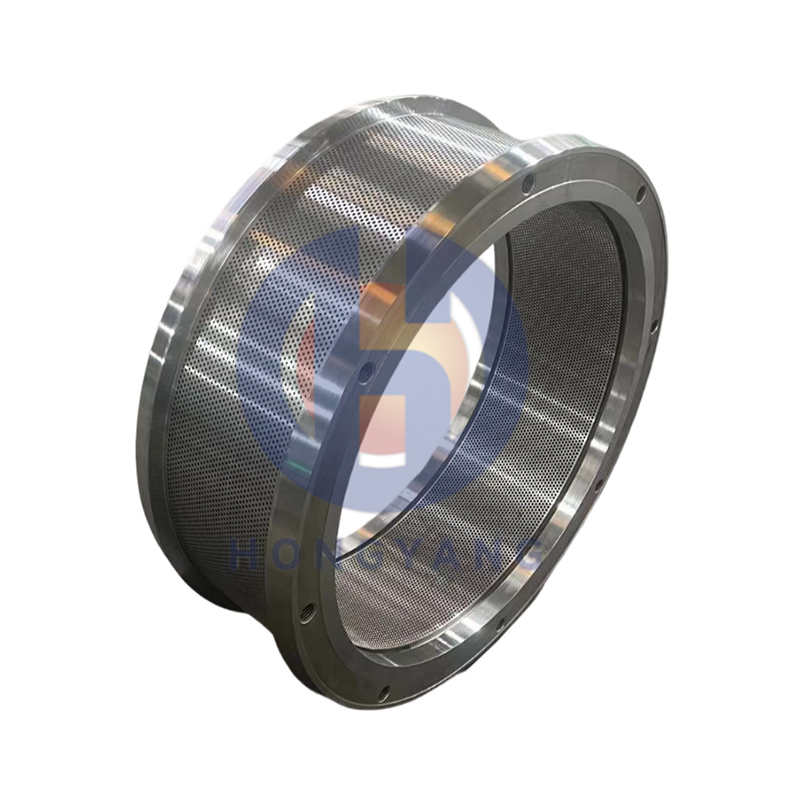

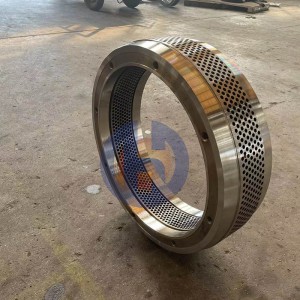

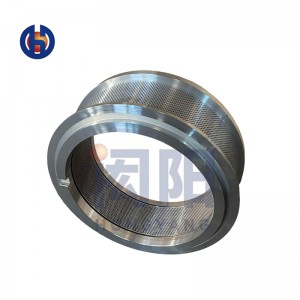

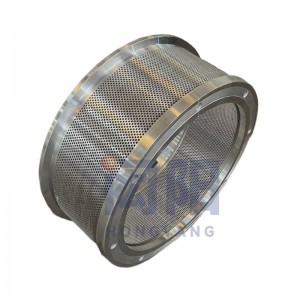

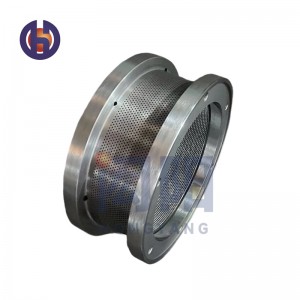

Ring Die Awila420 Pellet Die Awila 420

Ulwazi lweMveliso

Ii-Pellet Mills ngoomatshini abasetyenziselwa ukucubungula imathiriyeli ekrwada kwiipellets. Ezi pellet zingumthombo wamandla osebenzayo kwaye zisetyenziswa ngokuqhelekileyo kwiinkqubo zokufudumeza kunye nezityalo zamandla. I-ring die licandelo elibalulekileyo le-pellet Mill, enoxanduva lokubumba izinto ezikrwada zibe ziipellets.

Uyilo lokufa kweringi luchaphazela ngqo isivuno kunye nomgangatho weepellets eziveliswayo. Iipateni zokudlula kunye nemilinganiselo kuyilo lokufa kweringi zibalulekile ekumiseleni ubungakanani besuntswana kunye nokumila. Ngepateni yokupasa echanekileyo, abasebenzisi banokuvelisa iipellets zobukhulu obahlukeneyo kunye neemilo ngokweemfuno zabo. Ngoko ke, kubalulekile ukuqinisekisa ukuba ufumana umsesane wokufa ngepatheni yokupasa elungiselelwe uhlobo lweepellets ozivelisayo.

Ngokufa kweringi elungileyo, abasebenzisi banokufikelela kwi-pellet density ephezulu, okuthetha ukuba iipellet ezininzi zinokupakishwa kwiindawo zokugcina. Ukongeza, iipellet ezixineneyo kunye nezithambileyo zisebenzisa amandla amancinci xa kufikwa kwezothutho, nto leyo ekhokelela kwiindleko zokuhamba eziphantsi. Ngale nto, iipellet zakho ziya kuba nomonakalo omncinci kunye nokwaphuka ngexesha lokuhamba, ukuqinisekisa ukuba uyahlawulwa ngayo yonke ibhegi ethunyelweyo.

Iphakheji yeMveliso

1. Ngokuqhelekileyo, umsesane wokufa uya kusongwa kakuhle kwifilimu yeplastiki engenamanzi.

2. Umsesane wokufa ufakwe kwimiba yeplanga okanye ugxininiswe kwiipaliti (ngokwesicelo sabathengi), kwaye emva koko ulayishwe kwizikhongozeli.

3. Iphakheji esemgangathweni yokuthumela ngaphandle, ikhuselekile kwaye izinzile, efanelekileyo kuthutho olude.

Umboniso weMveliso

Sinokubonelela ngeentlobo ezahlukeneyo zokufa kweringi. Sinokwenza ngokwezifiso ubungakanani kunye nokuma kwakho ngokomzobo wakho.