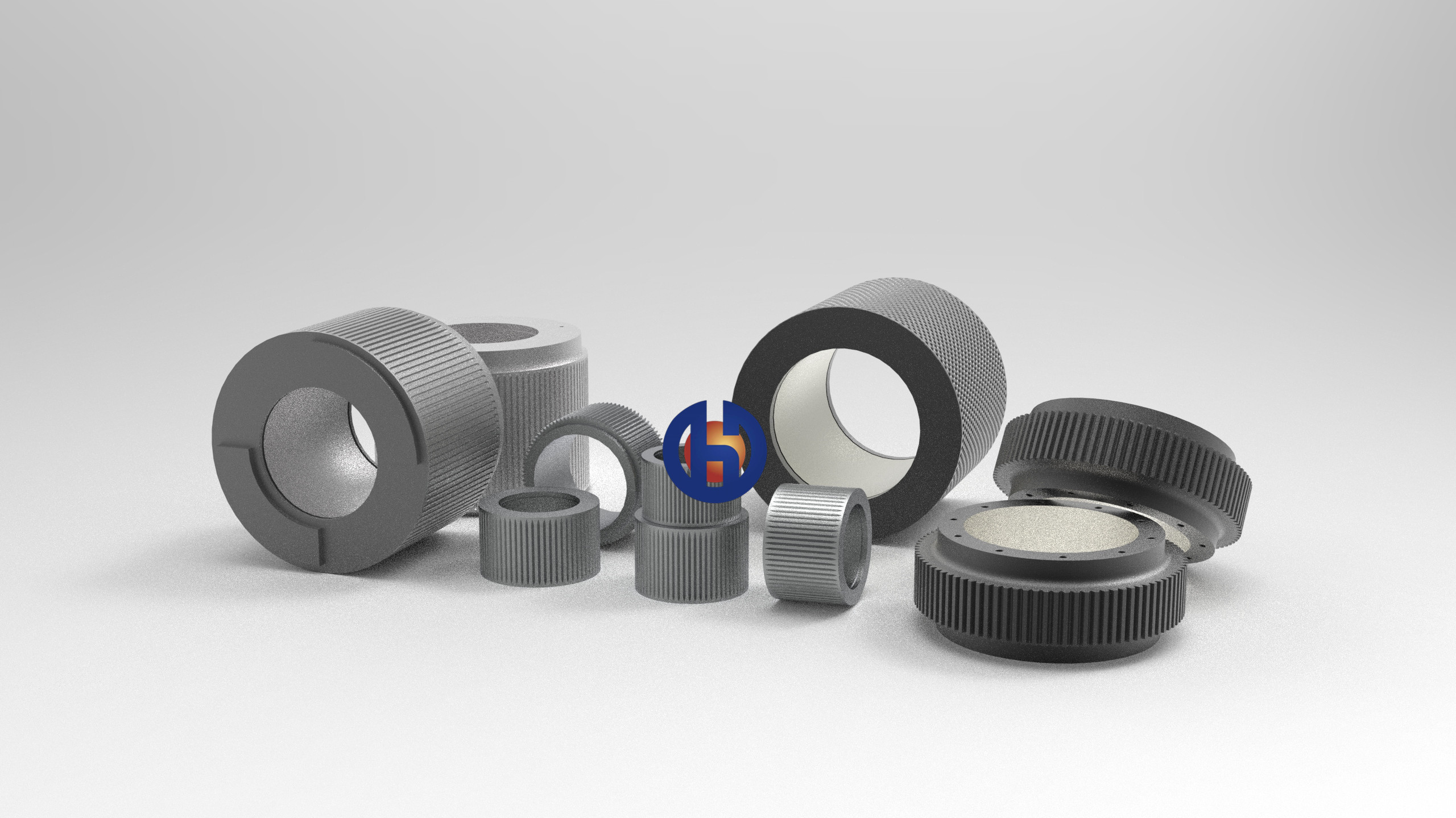

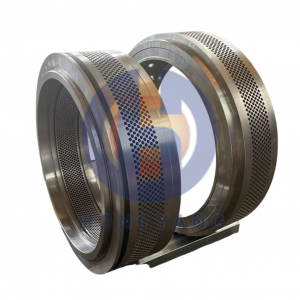

I-Roller Shell Mill yezahlulo ze-Spare ye-Pellet Machine

I-Fit yokuCofa iRola kunye neRingi Die

Ngaphambi kokufakwa kwe-press roll, i-sundries kwi-hole yendibano iya kuhlanjululwa ngokucophelela kwaye igcobe. Icala elikhulu lomqulu wasekhohlo liya kujongana phezulu ukuya ekunene, kwaye icala elikhulu lasekunene liya kujonga phantsi ukuya ekhohlo. Ipleyiti yokucofa iya kufakwa emngxunyeni.

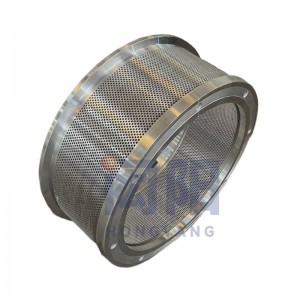

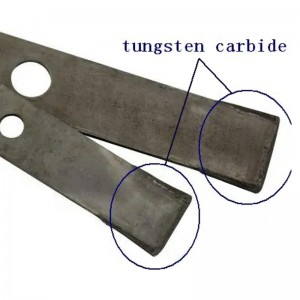

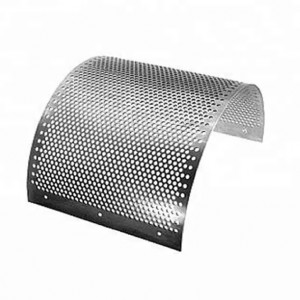

1. I-roller die clearance ihlengahlengiswa ngokuguqula i-eccentric shaft anticlockwise ukwenza i-clearance ibe yincinci kunye ne-clockwise ukuyenza ibe nkulu. Umsesane omtsha wokufa uya kuxhotyiswa nge-press roll entsha kunye nokukhutshwa malunga ne-0.2mm kunye nokukhutshwa kwexesha eliqhelekileyo lemveliso ye-0.3mm. Ukulungelelaniswa kwe-gap roll die ibaluleke kakhulu. I-gap incinci kakhulu, i-roll ifa ngokuqhagamshelana ngokuthe ngqo, ukunxiba kuyanda, kwaye umphetho womngxuma wophondo wonakaliswe ngokuqengqeleka; Ukuba ukucocwa kukhulu kakhulu, umphumo uya kuchaphazeleka, kwaye umatshini kulula ukuvalelwa, okanye awukwazi ukuhlanjululwa. Amava abiwe yinkosi endala kukuba xa i-ring ring iguqulwa ngesandla, kungcono ukuba i-pressure roller iphenduke i-passively.

2. Ukulungelelaniswa kwe-axial ye-press roll kunye ne-ring die ikakhulu kuthetha ukuba indawo ye-axial ye-press roll kunye nobuso obusebenzayo be-ring die kufuneka ichaneke. Uninzi lokushicilela ubuso obusebenzayo buyi-4mm ububanzi kunobuso obusebenzayo bomsesane wokufa. Eyona nto ifanelekileyo kukusabalalisa ngokulinganayo i-2mm ngaphambili nangasemva. Indlela yokulinganisa kukulinganisa umgama phakathi kobuso besiphelo somsesane wokufa kunye nesiphelo sobuso be-press roll kunye ne-vernier caliper enokulinganisa ubunzulu, uze ubale ukuba kunengqiqo ngaphambi kokwenza uhlengahlengiso. Ukuba utshintsho luyenzeka, ngokuqhelekileyo luyenzeka emva kokutshintshwa kwe-shaft engundoqo yokuthwala, okanye i-non-standard pressure rolls kunye nezixhobo ezisetyenzisiweyo.