1. Ngokufika kwexesha le-antibiotic-free, izinto ezinobushushu ezifana ne-probiotics zongezwa ngokuthe ngcembe kwi-pellet feeds.Ngenxa yoko, ngexesha lenkqubo yokuvelisa ukutya, iqondo lobushushu liya kuba nefuthe elibaluleke kakhulu kumgangatho wokutya kwepellet.Ukuba iqondo lobushushu liphezulu kakhulu ngexesha lemveliso ye-pellet feed, iya kubulala izinto ezingeva lubushushu ezifana neprobiotics.Ukuba iqondo lobushushu liphantsi kakhulu, izinto zebhaktheriya kwi-feed ye-pellet aziyi kuvalwa ngokupheleleyo, okukhokelela ekuveliseni ukutya kwe-pellet.Umgangatho awukho mgangathweni.Ke ngoko, ukuze kuthintelwe impembelelo yobushushu kuvavanyo, olu vavanyo kukufunda impembelelo yobushushu bobushushu kunye nomlinganiso womngxuma wokufa kumgangatho wokulungiswa kwesondlo se-pellet phantsi kweemeko zobushushu obuphantsi, ukuze kufundwe ukuveliswa kweepellets. ukutya kwepellet phantsi kweemeko ezihambelanayo emva kokuba izinto eziluhlaza zivuthiwe.Ingaba igcwele kwaye ihambelana nemigangatho yovavanyo lomgangatho wamasuntswana.Eyona njongo iphambili yolu vavanyo kukubonelela ngesikhokelo esithile sethiyori malunga nokuveliswa kokutya kweepellet zemfuyo.

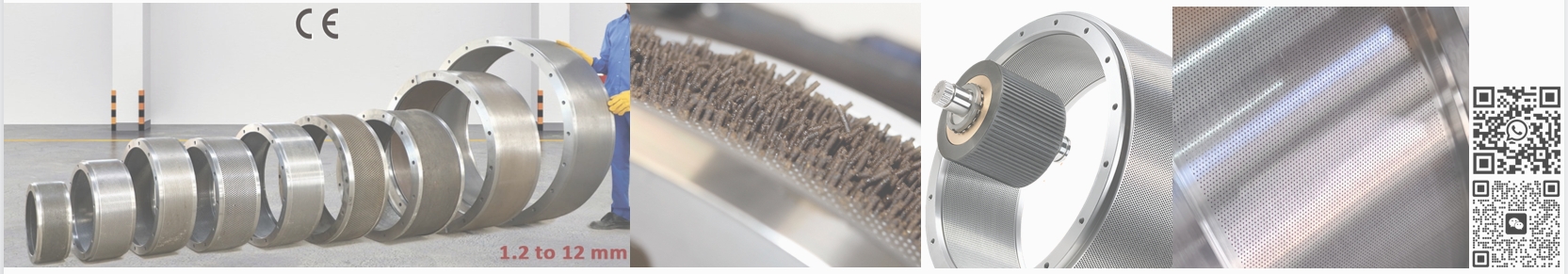

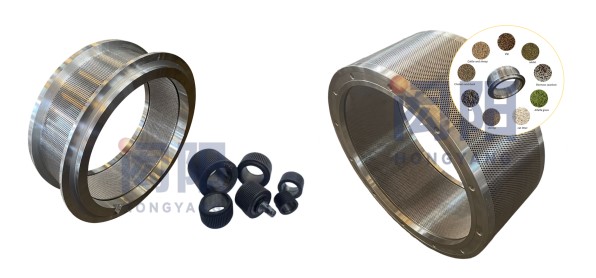

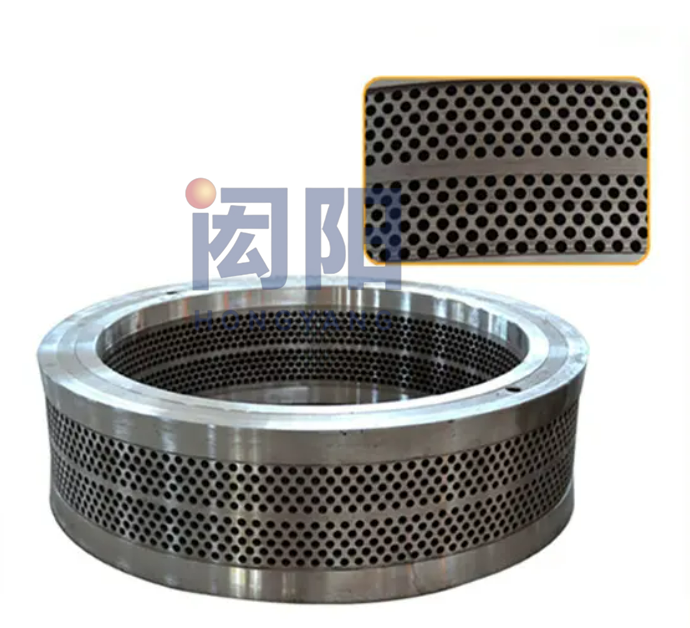

2.1 Izithako eziphambili zovavanyo lokutya kunye ne-pellet ekrwada zibandakanya: umbona, umgubo wentlanzi, ityuwa, i-methionine, i-threonine, njl. njl. iimfuno, kwaye emva koko wavuthwa.Emva kokupholisa, izinto ezinobushushu ezifana ne-probiotics zongezwa, kwaye ekugqibeleni zifakwe kwi-particle.Amaqondo obushushu eepellets zesondlo ezibekwe ngokwemeko ziqhelekile ziyi-60, 50, 40, kunye ne-30°C, kwaye ubude kunye nobubanzi bemingxuma yokufa buba yi-7:1, 6:2, kunye ne-10:1, kunye ne-300 mg/kg yeprobiotic. izinto zongezwa ngokusekelwe kwizinto zokuvavanya., kunye nokushisa kwesondlo se-pellet kwakhona kufuneka kuhlanjululwe ukukhusela umsebenzi weprobiotics.Ukongeza, ezinye iivithamini kufuneka zongezwe kwikhilogram nganye yokutya kwe-pellet ukuqinisekisa ukuba izakhi zesondlo ze-pellet feed zinokuhlangabezana neemfuno zesizwe sokutya.

2.2 Ukwenza iisampulu kunye nokuqokelela iisampuli

Ukuze kuqinisekiswe ukuba ukutya kwe-pellet kuveliswa kuyafaneleka, emva kokuba ukutya kwe-pellet kuveliswa, kuyimfuneko ukukhetha ngokungenamkhethe ukutya kwe-pellet ukuze kuhlolwe umgangatho.

2.3 Imigangatho kunye neendlela zokuhlola umgangatho

2.3.1 Iqondo le-gelatinization yesitatshi

Xa uvavanya iqondo le-gelatinization yesitatshi kwiisampuli zokutya kwe-pellet, abasebenzi banokusebenzisa i-amylase ukuyifumanisa.Yongeza i-amylase kwi-starch, kwaye ubale ukusabela kweekhemikhali phakathi kwe-amylase kunye nesitashi.Ekugqibeleni, yongeza isisombululo se-iodine, kwaye ugwebe iqondo le-starch gelatinization ngokujonga ubunzulu bombala wesiphumo sokusabela kweekhemikhali.

2.3.2 Ukuqina kweepellets zefidi

Ukuze uvavanye umgangatho we-pellet feed, ubulukhuni bayo bufuna ukuvavanywa.Umgangatho wobulukhuni be-pellet feed kufuneka ubhekiselele kulwazi olufanelekileyo.

2.3.3 Isalathiso sokunyamezela kwifidi yeepellet

Beka i-pellet feed kwibhokisi ejikelezayo kwaye uyijikeleze kwi-50r / min imizuzu engama-20.Emva kokuyeka, khupha i-pellet feed kwaye emva koko ulinganise ubunzima obuseleyo be-pellet feed kwaye uyiveze kwi-m.

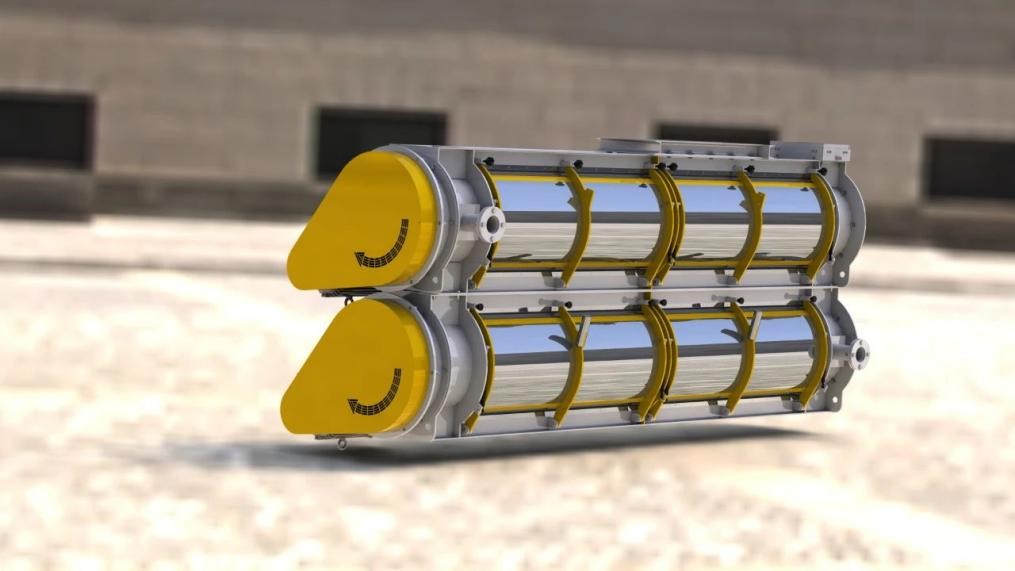

3. iziphumo zovavanyo

3.1 Iimpembelelo zomgangatho wesondlo, ubushushu kunye nomlinganiselo wedayamitha yomngxuma kumgangatho kunye nobunzima bokutya kweepellet.Olu lingelo luphonononga ubukhulu becala ipateni yotshintsho lomgangatho wokutya kwepellet phantsi kweemeko zobushushu obuphantsi.Ezona zixhobo ziphambili zibandakanya umbona, umgubo weembotyi zesoya, njl. njl., ezicutshungulwayo zivuthwe.Emva koko, emva koko i-granulated kumaqondo aphantsi.Kwafunyaniswa ukuba umgangatho we-pellet feed awuchaphazeli nje kuphela umlinganiselo wezinto eziluhlaza, kodwa kunye nobubanzi bomngxuma wokufa womatshini wokucubungula.Xa ubushushu bokuvelisa i-pellet feed iphezulu, umlinganiselo ukuya kububanzi kunye nobude be-membrane umngxuma womatshini mkhulu, kwaye ukuqina kwe-pellet feed eveliswayo kuphezulu, kodwa kuya kuchaphazela umsebenzi weprobiotics kwisondlo, kwaye amandla asetyenzisiweyo ekuveliseni ukutya kwepellet aya kuba nawo aya kwanda ngokufanelekileyo.Iziphumo zovavanyo zibonisa ukuba ukuze kuqinisekiswe ukuba umgangatho wesondlo se-pellet esiveliswayo ufikelela kumgangatho, kufuneka uveliswe phantsi kweemeko ezinjalo zemveliso.

3.2 Impembelelo yobushushu bokulungisa kunye nedayamitha yomngxuma wokufa kwiqondo legelatinization yestatshi kwifidi yepellet.Emva kothotho lwezifundo zovavanyo, kwafunyaniswa ukuba ubushushu bokulungisa oomatshini kunye nedayamitha yomngxuma wokufa kunempembelelo ebaluleke kakhulu kwiqondo lesitatshi legelatin lokutya kwepellet.Phantsi kweemeko ezifanayo zobushushu, i-diameter encinci ye-die hole, impembelelo enkulu kwiqondo le-gelatinization yestatshi kwi-pellet feed.

3.3 Impembelelo yobushushu bobushushu kunye nedayamitha yomngxuma wokufa ukuya kumlinganiselo wobude kwiqondo lokugcinwa kweeprobiotics kwigranules.Emva koluhlu lwezilingo, kwafunyaniswa ukuba umsebenzi weprobiotics uchaphazeleka kakhulu ngubushushu.Ukuba iqondo lokushisa liphezulu kakhulu ngexesha lokuvelisa ukutya kwe-pellet, kuya kunciphisa ngokuthe ngqo umsebenzi weprobiotics.Ngoko ke, ukwenzela ukuba kuqinisekiswe ukugcinwa kweprobiotics ngexesha lokuvelisa ukutya kwe-pellet kunye nemigangatho yokuvavanya umgangatho we-pellet feed, kuyimfuneko ukuvelisa ukutya kwe-pellet phantsi kweemeko eziphantsi zokushisa.

4. Isiphelo

Ngolu vavanyo, kunokufunyanwa ukuba umgangatho, ubunzima kunye nenani le-probiotics kwi-feed ye-pellet ayichaphazeli nje kuphela ukushisa kwemveliso, kodwa kunye nobubanzi bomngxuma wokufa.Ngokusebenzisa uchungechunge lwezifundo, kwafunyaniswa ukuba ukusebenzisa izinto ezivuthiweyo zokuvelisa ukutya kwe-pellet phantsi kweemeko zobushushu obuphantsi kunceda ekuphuculeni umgangatho kunye nobulukhuni be-pellet feed;phantsi kweemeko ezifanayo zobushushu, okukhona umlinganiselo wokufa komngxuma wokufa uphezulu, kokukhona ukuveliswa kweepellets kungcono.Amandla asetyenzisiweyo kwinkqubo yokutya aphezulu.Ngokusebenzisa imifuniselo, kwafunyaniswa ukuba esona sisombululo sisiso sokuvelisa ukutya kwe-pellet kukusebenzisa izixhobo ezinomlinganiselo womngxuma wokufa oyi-6:1 kubushushu obungama-65°C ukuvelisa ukutya kwe-pellet kowona mgangatho uphezulu.

Ixesha lokuposa: Jan-10-2024